Facts about WoodPlast

Engineers and architects are one of those people who are always looking to optimize raw materials and modernize designs. Progress happens equally in all different areas of the industry. In fact, no matter how much the design of the exterior decor has grown; Building materials are also more efficient; They have become more efficient and cost-effective. Plast wood sheet is one of the modern developments.

Such products are a combination of the advantages and possibilities of wooden and plastic profiles and have provided many capabilities to architects. These types of products are actually a type of plywood composite that is designed and made from a combination of plastic and wood powder. The purpose of producing Plast wood is to eliminate the limitations and disadvantages of different types of wood fibers or profiles.

Vanwood is a manufacturer of various types of polywood composites in Iran.

Of course, materials are used in various industries, one of which is architecture and construction, which we are talking about throughout the leading article. Composites are usually produced and marketed in various single to multi-layer forms. Throughout the article, we intend to assess all aspects of product use in a specialized way. Eventually you will be able to decide whether to buy Plast van Wood profiles.

Facts about WoodPlast

What is Plast wood?

Improper use of plastic and its various compounds has been a great harm to nature. On the other hand, the quality of products made of wood has caused people to tend to cut more trees to produce more wood profiles. In fact, the design and production of this sample of composites has done a great service to the environment.

In fact, by producing this type of composites, which is known in the world as wood plastic composite or its abbreviation wpc, which by producing these products, a large number of trees can be cut down, and by using branches or even carpentry waste, this product can be produced and marketed.

Plast wood is actually an ideal alternative to all types of plastics; because recycled plastics are used in its production. As a result, the problem of previous years, which was related to the disposal of non-biodegradable plastic waste; it is completely solvable with this method.

Using Plast wood profiles:

Landfill problems are solved.

Less plastic is produced; because plastic waste is used in their construction.

Fewer trees are cut down; as a result, it serves the environment.

The quality, durability and strength of the products increase.

They have created many applications.

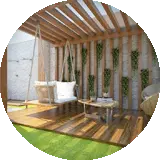

One of the most important things to say about Plast wood; such creative designs are widely welcomed by the people. In fact, the applications of such products have increased a lot today and people tend to use various examples of it to design floors, facades, etc.

Facts about WoodPlast

How is Plast wood sheet made?

Plastic wood products known as WPC; summary Wood-plastic composites. The process of making and preparing them is very similar to preparing different types of PVC. Since such products have high sales; the final formulas for making them are among the golden secrets of manufacturers. Therefore, information about this is very limited and general.

We know that recycled plastics are used in the production of Plast wood sheets. As a result, the base and raw materials used in the manufacture of products; Recycled plastic material and fibers of larch tree or other trees. In fact, the wood fibers of this tree are made into composites called thermowood larch, which are used for various applications, especially in the preparation of various types of plastic sheets.

Of course, the wood of this tree is not the only wooden profile that can be used to prepare such products; but in general, wood should not have an element called tannin. In addition to basic materials such as wood and recycled plastic, some additives must be added to factory-made boilers.

Ingredients are:

Lubricants and waxes; it causes mobility in materials and their proper mixing.

Stabilizers; Helps to mix.

Shock correction materials; They reduce the fragility of raw materials.

And some other factors that ultimately improve the process of chemical transformation, discoloration and shaping of the final product.

Advantages and disadvantages of composite plastic sheet

This product, like most products, has advantages and disadvantages. People choose one of them according to the type of their needs and the coordination of the products with the level of their demands, budget and facilities. In the following, we will examine the advantages and disadvantages of Plast wood.

Facts about WoodPlast

What are the advantages of composite?

In fact, the advantages of such products far outweigh their disadvantages, and this is what has made their use so popular. Plast wood has good resistance in different climatic conditions. Therefore, it can be used easily and in any area. Styling is another feature of composites that has expanded its use in various fields.

Cleaning products made from such raw materials; it is easier than other products because they are more resistant to staining. Other advantages of wood-plastic composites include the following:

Relatively high resistance to rot, corrosion and cracking

Extremely varied in design and color

No need for maintenance

Cost-effective compared to thermo wood

Disadvantages of wood-plastic composites

Even if you choose the best view of Plast wood; They still have a relatively abnormal appearance. It means the polish and beauty that is obtained from natural wood for you; much more than such products. If you use low quality products; in some cases, they may be completely slippery and unsafe. Especially if they are used in the preparation and manufacture of flooring.

Other disadvantages of composites are:

When their useful life is over; symptoms of failure are well represented in them.

They bend more than wood.

Of course, Van Wood guarantees Hood products.

Is Plast wood profile compatible with the environment?

If we consider only two great services that Plast wood sheet does to the environment; we will find that such products are completely compatible with nature and the environment. Products have reached out to nature in two ways:

Removal of plastic waste and recycling of plastics, which leads to non-reproduction of plastics. As a result, the waste that nature had to endure for millions of years; it has been deleted.

Reduce tree felling; whereas products are suitable for the manufacture of many pieces of equipment; there is no need to use natural wood profiles and cut down trees.

Therefore, it is found that the production of such products, by reducing plastic waste and preserving the remaining trees on Earth, is a great gift to nature.

On the other hand, such products can be recycled after the end of life and use, in this regard, a produced plastic can be recycled again and again and be in the recycling period. As a result, such products contribute to the environment in all dimensions. Conveniently, the human desire to expand modernity in the form of such products continues; without harming the environment.

Does Plast wood need a special paint?

When customers ask such a question; do they really want to know that composites, like MDF or other composite products, look ideal or, like chipboard, have to think about a special color or coating for them ?!

Product panels are produced and marketed in different types. Some specimens are raw and have an unsightly appearance; some of them have beautiful and attractive coatings and are used in the same way. Therefore, it is possible to paint raw plastic wood profiles. Of course, this depends entirely on the taste of the customers, which of the product samples they prefer to use.

To paint plastic wood composites, you must follow the following steps:

First, the surface of the composite should be well sanded and polished (without sanding, if the surface of the product is clean and free of any contamination, it can be painted).

Remove excess dust.

Apply a layer of wet primer on the surface with special brushes and allow to dry.

Apply a layer of paint on the product and complete it with wood filler.

Is Plast wood sheet fire resistant?

Additives and major raw materials used in the production of Plast wood sheets; they are kind that have good resistance to ignition. As a result, such products fall into the category of fire-resistant products. Whereas the previous examples of composites, namely wood and plastic, behaved completely differently and caused serious damage.

The existence of such features and capabilities makes the price of Plast wood usually higher than other composites produced. In fact, the price of products is based on the performance they offer; it turns out and plastic wood-plastic composites are among the best in this regard.

Such products are not only highly resistant to fire, but also to erosion or weathering. Their rigid structure gives rise to such capabilities. They are even more durable than plastic beams and do not have the sensitivities of wood. Therefore, in terms of use in environments that have a high risk of fire; it is very convenient.

In fact, Van Wood plastics are slow-burning and have been certified as slow-burning. For example, I am referring to the Isfahan metro project of Shiraz Gate Station, in which a 4 x 16 cm ceiling Louvre profile of Plast van Wood was used, which due to the sensitivity of metro stations and the need for high safety in urban train stations, this product was sent for testing. After different tests at different temperatures, this product was confirmed as a slow burner.

Eventually

Plastic wood is one of the composite products that has provided great services. In fact, products are a type of composite that is made to a certain degree from natural wood fibers or thermowood and recycled plastics. The combination of such raw materials makes the produced composite have more advantages than wood or plastic samples.

The service that products provide to the environment; it is far more valuable than their other benefits. Such products contribute to human survival on earth by reducing tree felling and reducing plastic waste. They are also fire resistant and can be coated or painted.

Van Wood is made of wood but beyond wood

Wpc.ir

02126753345

09383603809

Click on the link below to view Van Wood projects

Also, click on the link below to know the price of Plast Van Wood