Wood plast (wpc)

Plast wood (wpc) is generally composed of wood, thermoplastics and a number of additives, each of which can include the following:

Wood section: wood powder, wood fiber and so on.

Thermoplastics: Mainly new and recycled plastic materials such as polyethylenes, polypropylenes and polyvinyl chlorides (PVC). Of course, polyethylene wood plastics are more common.

Additives: colorants, couplings, UV stabilizers, foaming agents and lubricants that help to achieve the desired final product.

Benefits of Plast wood (plastic wood)

- Moisture resistance

- Resistance to fungi and mold

- Crack resistance

- Resistance to termites and insects

- Environmentally friendly and safe (prevent the felling of trees and preserve forests)

- Recyclability

- Washable with mild detergents

- Possibility of resistance to some acids

- Sound and thermal insulation

- Antibacterial properties

- Possibility of relative resistance to scratches and scratches

- Possibility of fire resistance (slow burning)

- Slip resistance

- Possibility of relative resistance to UV rays

- Adaptation to different weather conditions

- No need for paint coating

- Has a useful life of about 20 years

Physical properties of Plast wood:

Due to the inherent structure of Plast wood, which is composed of wood and plastic, it has very little water absorption, and this has caused swelling and bloating when exposed to aquatic environments. Therefore, due to this property, Plast wood is used in environments exposed to water and moisture, such as bathrooms, toilets and kitchens. Plast wood also has good flexibility and high durability.

Mechanical properties of Plast wood:

The following section presents some important mechanical properties of Plast wood.

Shear strength: about 27 MPa

Flexural strength: about 40 MPa

Certificate link

Plast wood applications

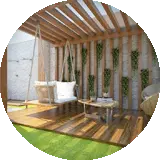

- Plast wood flooring

- Polywood building facade

- Plastic wood wallcovering

- Pergola Wood Plast

- Plast wood pavilion

- Plastic wood fence

- Polywood vase

- Wood plast bench

- Plast wood false ceiling

- Plastic wood partition

- Plast wood Louvre

- Polywood frames doors

woodplast production process

- Production of Plast wood by extrusion method

- Production of plastic wood by injection molding method (Injection Molding)

- Production of Plast wood by compression molding method

- Production of plastic wood by plate molding method (Plate Molding)

- Production of Plast wood by Pultrusion method

- Production of Plast wood by Fused Layer Modeling

Plast wood manufacturing standards

- Fire resistance

- Abrasion resistance

- Slip resistance

- Bending strength

- pushing resistance

- Abrasion resistance

- Control dimensions and sizes

- Density control

- Humidity control

- Resistance to boiling water

- Resistance to thermal deformation

- Resistance to aging

- Resistance to decay

- Resistance to fungi

- Resistance to chemicals

- Resistance to termites and insects

- Resistance to ultraviolet (UV) rays

- Resistance to inflation

- Impact resistance

- Surface smoothness control

- And …

Van Wood Company, a manufacturer of various types of plastic wood profiles, has obtained a certificate from Razi Institute of Metallurgy.

Certificate link

Execution and installation of Plast wood

To install profiles; wood profiles, metal profiles and even Plast wood profiles can be used to create substructure. Painting metal profiles in order to prevent rusting of the substructure is one of the important points that must be considered.

If the work floor is uniform and there is no difference in height, then it is enough to install the profiles in a direction perpendicular to the installation of plastic wood profiles. However, if the working floor is not uniform, a false flooring system should be used to smooth the slope of the floor

It is better to place the substructure profiles at a distance of 25 cm from each other. Of course, this depends on the use of the place. For example, if it is to be used in crowded and touristy places, it is better to reduce this distance to less than 25 cm. When you put two plastic wood profiles together, put a distance of about 1 cm between them so that there is no problem due to expansion and contraction. It is better to create a slope of about one percent in the whole work so that if water remains on the floor, it will come out slowly due to this slope.

Click on the link below to view Van Wood projects

Also, click on the link below to know the price of Plast Van Wood

Phone Call:

09383603809

02126753345